Graphics cards are very, very complicated. The nVidia Titan X GPU, for example, is made up of 8.1 billion transistors, each of them literally large as two dozen silicon atoms. Stop for a moment and think about it! Not surprisingly, given the magnitudes involved, the path that leads from the design table to the factory and gradually up to our computer is just as complex and fascinating.

Moreover, we are talking about one of the most advanced industries in the world, as well as one of the most expensive. Analysts indicate that AMD is already under $ 150 million for the development of its next-generation graphic architecture. In this article we will give you an idea of how this industry works, and how the best graphics card that we mount in our computers are made.

Manufacturing of graphics card

Companies like Nvidia and AMD are defined, in English, “fabless producers” of best graphics card. Which does not mean that they are “fabulous”, but that they deal essentially with the specifications and design of the GPU, in essence a very complicated variant of the concept “this put it here, put it there”. AMD and Nvidia, in fact, spend millions of dollars to create diagrams like this.

Production

The actual production of the GPU is instead entrusted to external companies, such as the giant TSMC (Taiwan Semiconductor Manufacturing Company). It is a relationship similar to that which intervenes between Apple and Foxconn when it comes to making an iPhone, apart from the fact that it is the same TSMC that contributes to produce the SoC (System on a Chip) A8 that we then find within our iPhone 6 and iPhone 6 Plus. But not all GPUs produced are the same: due to the construction process, it may happen that chips coming out of the same production line are slightly different. An aspect that is technically called Binning, according to which the theoretically identical chips are categorized, leaving a production line based on their thermal and frequency performances.

GPUs with a higher ‘binning’ are usually those capable of operating at a higher clock frequency than those with a lower ‘binning’. The basic specifications are designed according to a minimum common denominator (all GPUs must have at least some degree of performance to be accepted), and some third-party assemblers, such as ASUS, for example, can make lots of the best GPUs to create cards like the Strix 970, which is capable of 10% higher performance (and above) compared to the 970 reference cards. Naturally, the number of these “super efficient” GPUs is limited in each of the production lots, so assemblers are always willing to pay more than the base price to make sure.

Performance

For us players it is important to understand that binning implies that many GPUs fail to achieve the minimum performance required. Because of the complexity of the chip-building procedures, it is normal for a large number of chips to be discarded: in some cases, as with the first generation of the Fermi-class GPUs – the GTX 400 series – the difference rate below 50 percent. And it is clear that if each GPU produced must discard another, the selling price can only go up.

Not all these scraps are to be thrown away, though. Some are not as faulty as others, and by disabling some of the problematic parts, or reducing the operating frequency, you can still make a video card, even if unable to provide the performance of those that are fully successful. This is the reason why it makes interesting cards based on the GTX 970: the outgoing 970 was a 980 that was not unusable, but could not reach the expected performance reference. In these cases, AMD and Nvidia can still use the chip produced, and consumers benefit equally, since they can buy video cards with reduced functionality, but always very interesting, at much lower prices.

Over time, the rate of valid GPUs compared to those discarded improves significantly: the more a manufacturer like TSMC works on the production of a particular chip, the more it can refine the process: take for example the Radeon 2xx series, GPU based on GCN graphics architecture (Graphics Compute Next) which is the foundation of all the modern GPUs of AMD, from HD 7000 onwards. It has been in production since 2012, and so TSMC has had a good three years to refine and adjust the production process.

Ending Note

Of course, the waste obtained from the production of a new GPU is substantially higher than those obtained from a chip a few years earlier. This means that AMD tends to spend less for each GPU, which ultimately reflects on the opportunity for each of us to get the same product at a more competitive price, without the producer having to revise his profit margins. Virtually the entire 2xx and 3xx series exist because the high production efficiency allows AMD to cut prices and reintroduce what were its flagship products on a market, so to speak, medium.

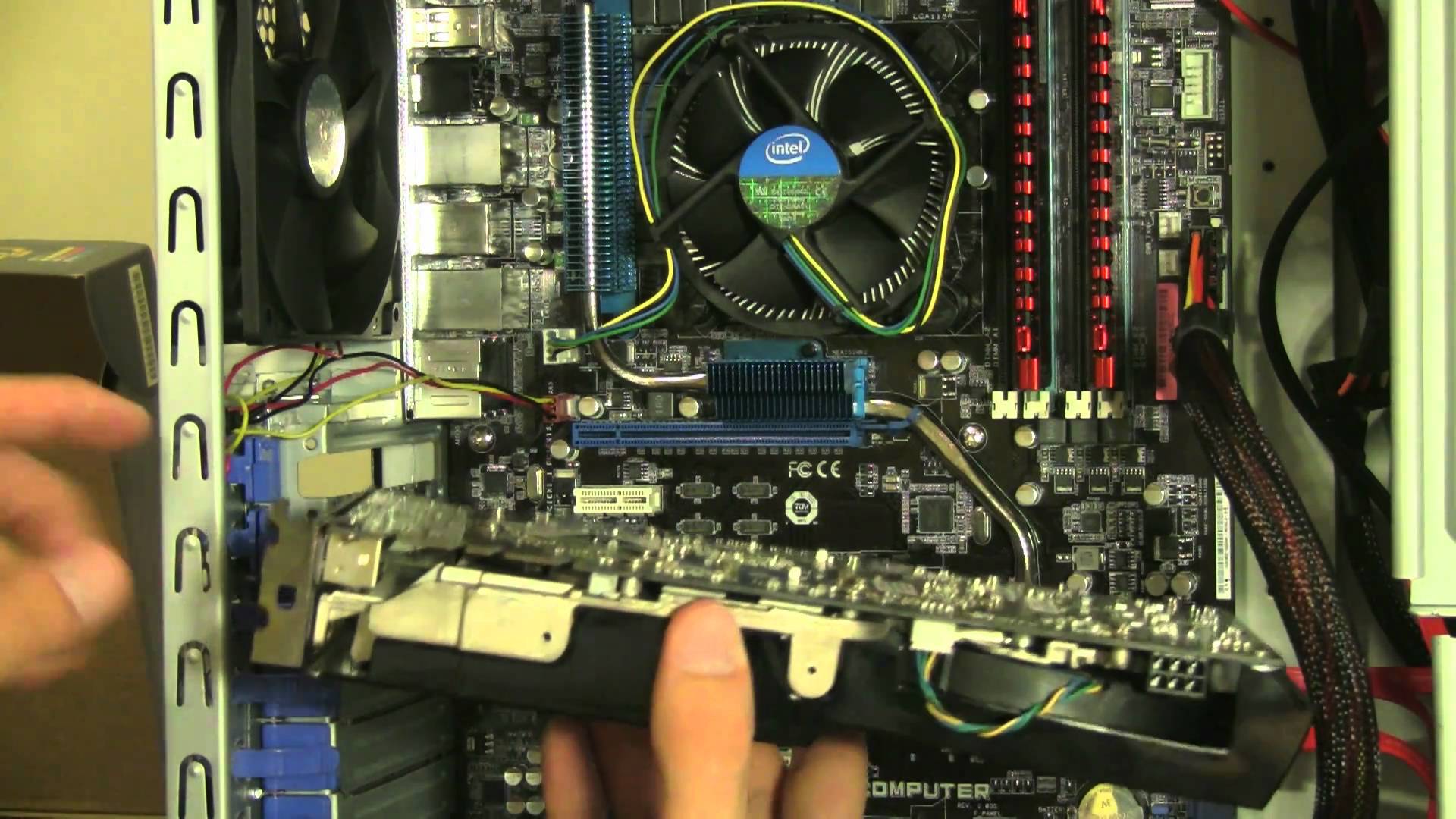

Once the construction process is over, AMD and Nvidia end up storing large amounts of chips, basically GPUs without … everything. Some of these are mounted on the “reference” cards and sold directly, like the 980Ti Reference, in fact. Most of the production, however, is purchased by third-party manufacturers like Asus and MSI, which add the other components, the cooling system and so on. These manufacturers, then, go to touch up the operating values, overclocking some variants in order to obtain superior performance compared to the “Reference” cards. And in the end, of course, the cards are boxed and distributed to stores, physical and online.